|

Cables:

|

|

Note:

|

- The information in this section is valid in the

United States, but is not applicable in most other

countries. For an overview of electrical

practice in other countries, see

Electricity around the World.

This web site is only a guide to common usage. It is not meant

to be a substitute for the National Electrical Code.

|

|

Abbreviations:

|

|

|

The electrical service in most American commercial buildings is what's

called "three-phase"; into every power box are run three "hot" wires, one

neutral wire, and a safety ground. The voltage measured (don't do this yourself)

between any two hot wires is approximately 208V. The voltage measured

between any one of the hots and the neutral is nominally 120V (but

usually somewhere between 110V and 125V).

There should be no measurable voltage between the neutral and the ground.

This power is "branched off" to individual circuits, each one (except

in the case of units such as air conditioners and other large motors)

having one hot, the neutral, and the ground, therefore being 120V.

The electrical cables which are approved for use in theatres typically

contain three wires: black, white, and green. The black wire is

the hot. The white wire is the neutral. The green wire is

the safety ground.

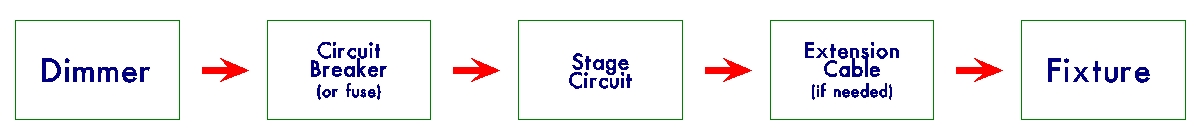

The path by which electricity gets from the dimmer to the lighting

fixture is this:

It's important (and, usually, legally mandated) that the dimmer, circuit breaker, stage circuit,

and extension cable all be rated to carry the same amount of current.

The table below shows the amperage ratings of various sizes of electrical

cable.

It's important (and, usually, legally mandated) that the dimmer, circuit breaker, stage circuit,

and extension cable all be rated to carry the same amount of current.

The table below shows the amperage ratings of various sizes of electrical

cable.

|

AWG

|

Maximum

Amperage

(at 120V)

|

|

0000

|

400

|

|

00

|

200

|

|

0

|

175

|

|

1

|

150

|

|

2

|

125

|

|

4

|

100

|

|

6

|

80

|

|

8

|

50

|

|

10

|

50

|

|

12

|

20

|

|

14

|

15

|

|

16

|

10

|

"AWG" stands for "American Wire Gauge" and is a measure of the

diameter of an electrical conductor; the lower the gauge, the

larger the wire. Note that the "0" is pronounced, "aught,"

so that "0000" is referred to as "four-aught".

The National Electrical Code mandates that cable used in theatres

be "jacketed" (having an outer insulation around the individually-insulated

inner conductors), stranded (as opposed to each conductor's being a solid

piece of copper), and rated for "hard" service. The standard cable

used in American theatre is 12AWG Type SO (The "O" stands for "oil resistant").

For certain uses (for example, twofers), type SJ or SJO (the "J" stands for

"Junior" service. The insulation on type SJ or type SJO cable is not as robust as that

on type SO cable) may be used.

In America, most dimmers are rated for 20 amps, so by the table, you should use

#12 cable with those dimmers. The connectors on those cables also need to be

rated for 20 amps.

|

|

Connectors:

|

Here are the connectors that are most commonly used

in American theatres:

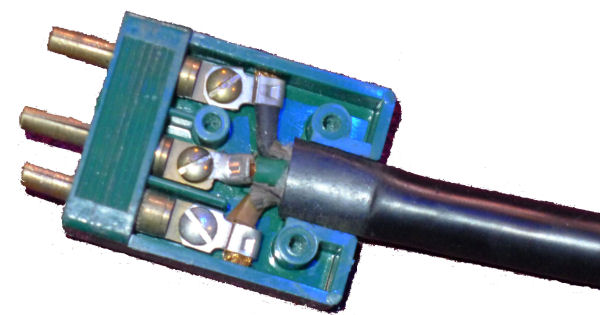

Stage Pin

(also known as "2P&G," "GPC," or

"two-pin and ground") This is the

connector found in most professional

theaters and on the equipment provided

by most rental houses.

|

|

Twistlock

|

|

Parallel Blade

(also known as "Edison," "PBG," or "Household")

|

|

There are two types of twistlock connectors in common use in North America:

|

|

|

The "Non-NEMA" type has the bend in the "ground"

pin facing away from the center of the connector.

It is obsolete and illegal to use in new construction.

It is typically rated for multiple voltages.

|

The "L5" type has the bend in the "ground" pin

facing toward the center of the connector. The L5

connector is rated for 125V, the voltage most

commonly used in North America. It is similar

in appearance to, but not compatible with,

the "L6" connector, which is rated for 250V.

North American theaters using twistlock connectors

most often use the L5-20, which is rated for 20 amps

at 125 volts.

|

Even though the stage pin is not a locking connector –

especially because it is not a locking connector –

it's important to make sure you have a secure connection when

plugging in a fixture or connecting two cables. The connectors

should fit snugly together; if they do not, one (or more) pin

has become compressed.

As you can see in the photograph above, each pin has a slot

down its length. Inserting, carefully, a pin spreader (available from

most theatrical suppliers) will decompress the pin and guarantee a

reliable connection, both mechanically and electrically.

Each type of connector has its advantages and disadvantages:

|

Connector

|

Advantages

|

Disadvantages

|

|

Stage Pin

|

- Easy to work with

- Found in most professional

theaters and rental houses

- Lies flat.

|

- Does not lock.

- Can only be purchased from theatrical suppliers.

|

|

Twistlock

|

- Guarantees a mechanical connection.

- Easy to find; often available at "big box" hardware stores.

|

- Does not guarantee an electrical connection.

- Bulky.

- More difficult to work on than pin connectors.

|

|

Parallel Blade

|

- Easy to find.

- Inexpensive.

|

- Connection is not secure, either electrically

or mechanically.

- Makes it more likely that cables and connectors

will not be rated for the electrical load they'll

be carrying.

- Can be used with ungrounded (2-wire) connectors.

|

|

|

Wiring:

|

When wiring a twistlock, the the ground (green) conductor is connected to the

"hooked" blade whether facing toward or away from the center of the connector.

The neutral (white) conductor is connected to the silver blade (which is smaller),

and the hot (black) conductor connects to the brass blade. Note that on some connectors,

the neutral blade may be brass, but the connecting screw, inside the connector and used

to attach the cable, will be silver.

On a stage pin connector, the ground (green) conductor is attached to the middle pin.

The neutral (white) is the pin closer to the ground, and the far pin is

the hot (black). Notice that the ground pin is slightly longer than the others, so that it is

the first to connect and the last to disconnect.

"Best practice", no matter which type of connector, mandates that the conductors be connected in this order:

…And discconnected in the reverse order. Never leave a cable partially built, with a male on one end and bare wires on the other.

When wiring connectors (of any type), make sure that the strain relief securely grabs the

outer insulation or "jacket", so as not to place undue stress on the individual

conductors.

"Best practice", no matter which type of connector, mandates that the conductors be connected in this order:

…And discconnected in the reverse order. Never leave a cable partially built, with a male on one end and bare wires on the other.

When wiring connectors (of any type), make sure that the strain relief securely grabs the

outer insulation or "jacket", so as not to place undue stress on the individual

conductors.

|

|